Why Round?

What if you could save 10%, 30% or even 50% of the wood you are currently using? And still get more heat from our stove than the stove you have now?

Some people might not want to get into the technical side of how or why but I will try to just give a few examples. With the patent, over 50 different styles of heaters can be produced.

I have heated with wood for 35 years and I even own a tree removal company. I have an unlimited supply of firewood but despite that, I couldn’t see continuing wasting my time and fuel on stoves I didn’t find very safe to operate.

Now, why were all the stoves in the past I used not really safe to operate?

Image 1 shows the inside of a square style firebox and the baffle. There is a wide open area that goes directly into the chimney pipe. The balloon, image 2, represents the hot gasses that would be flowing out into the chimney pipe. In order for the heat to be transferred to the firebox and be made useful, the heat has to touch a surface. As you can see in the example using the balloon, the balloon barely touches the top and bottom of the area inside the stove. (With smoke, heat is exchanged with convection and radiation, the example is an oversimplification of that.)

There is a lot of unused, wasted heat going into the chimney pipe.

A generic stove is shown here and it is a common design for the travel path of flues gasses out of stoves. The path is very sort and it is very easy for flames to travel into the chimney pipe. A lot of heat and the chance of flames going up the chimney means a high chance of a dangerous chimney fire.

The patented design is the solution to box stove problems.

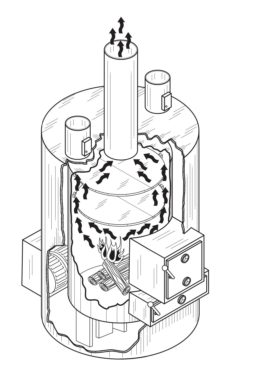

<< Here is a picture of a real cut away of the inside of the patent image, as you can see in the next image, the balloon I used in the previous box stove is now very compressed.

The baffle has only a very small gap for hot gasses to rise through. Also, the very narrow gap is forcing the hot gasses to touch the sides of the firebox.

The baffle in my stove design is a circle. The efficiency of a circle baffle is only possible with a circular vertical firebox. Also, a cylinder will expand and radiate heat evenly compared to a box stove.

As the hot gasses keep rising and passing each baffle, it is exchanging a lot of heat and it would be very hard for a flame to reach up into the flue pipe, which is located in the very center of the top. Smoke will emit radiant heat according to its temperature but convection is the primary mode of heat transfer.

Combined combustion chamber and heat transfer design allows longer residence time of the fuel, where high combustion temperatures and the combustion air are located. Primary and secondary combustion will happen in the same space but at different heights. What makes this design special is the combustion process and how the heat is transferred.

Just because the outside of the stove looks simple, there is a lot going on inside!

The pictures shows two baffles but that is only the start. The “Combustion Chamber Design/Heat Transfer Design” can have 2 baffles or 20. Passing each baffle (restricter plate) heat is transferred to the firebox and when reaching the flue, that is the center of the firebox, temperatures are greatly reduced.

As the fire is burning inside the stove, hot gasses are expanding. When the draft are is coming into the stove, that air is cold and will expand also. With all the gasses and draft are expanding, the baffles restrict movement up and just a tiny bit(any amount is significant) raises the pressure inside the stove making combustion even more efficient.

The world’s first ever wood-burning stove was patented in Strasbourg in 1557. Since 1557, there have been relatively few vertical cylinder shaped firebox stoves for smaller space heating. The wood stove manufacturing market very mature and innovation does happen often.

It seems that modern industries uses of cylinder combustion chambers are increasing. For example, large fluid catalytic cracking units (FCC) in modern chemical factories or oil refineries are tall cylinders and internal combustion engines use cylinders.

And still, I haven’t talked about View Factor and how surfaces reflect heat. A cylinder is a great shape for that but a box stove is not. You will see a lot of box stoves warp and crack because of their shapes.

It is Round For A Reason.

Patented in Canada (2,707,405) and United States (9182116)