Why Wood?

Why would someone want to heat with wood?

My dad told me the story of when and why he got a wood stove.

One winter morning the furnace in our house blew up, literally my brother had soot in his Cheerios.

Even living in a small town, he wasn’t able to get any help and in the dead of winter we went without heat for a week.

After that he swore he was never going through that ever again and installed a wood burning stove. At the time there were no EPA rules on wood stoves.

THEN, about 25 years later his basement got flooded and ruined his oil furnace. For him it was cheaper to put a wood furnace into the porch and heat the home that way. He did have a vent free propane space heater for back up.

There are a lot of reasons people use wood stoves, there are also a lot of non-traditional homes and a regular furnace just isn’t an option. Heating with wood is an affordable necessity.

I have heated my home for over 20 years and again, it was out of affordability and having the experience to know that I can heat my home and shop with wood. And wood heat just feels so good!

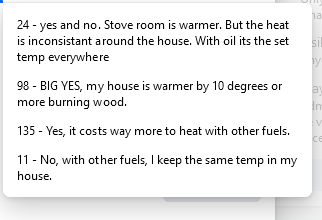

Thanks for making it this far! Here is a real poll I took on Facebook.

My main source of heat at my home is also my wood furnace. It seems it is cheaper to have a wood heating appliance versus having a brand new propane, electric, natural gas or heat pump installed. With firewood, you can depend on yourself for sourcing and processing your own heating fuel and you don’t have to worry about wild fluctuating prices of fossil fuels.